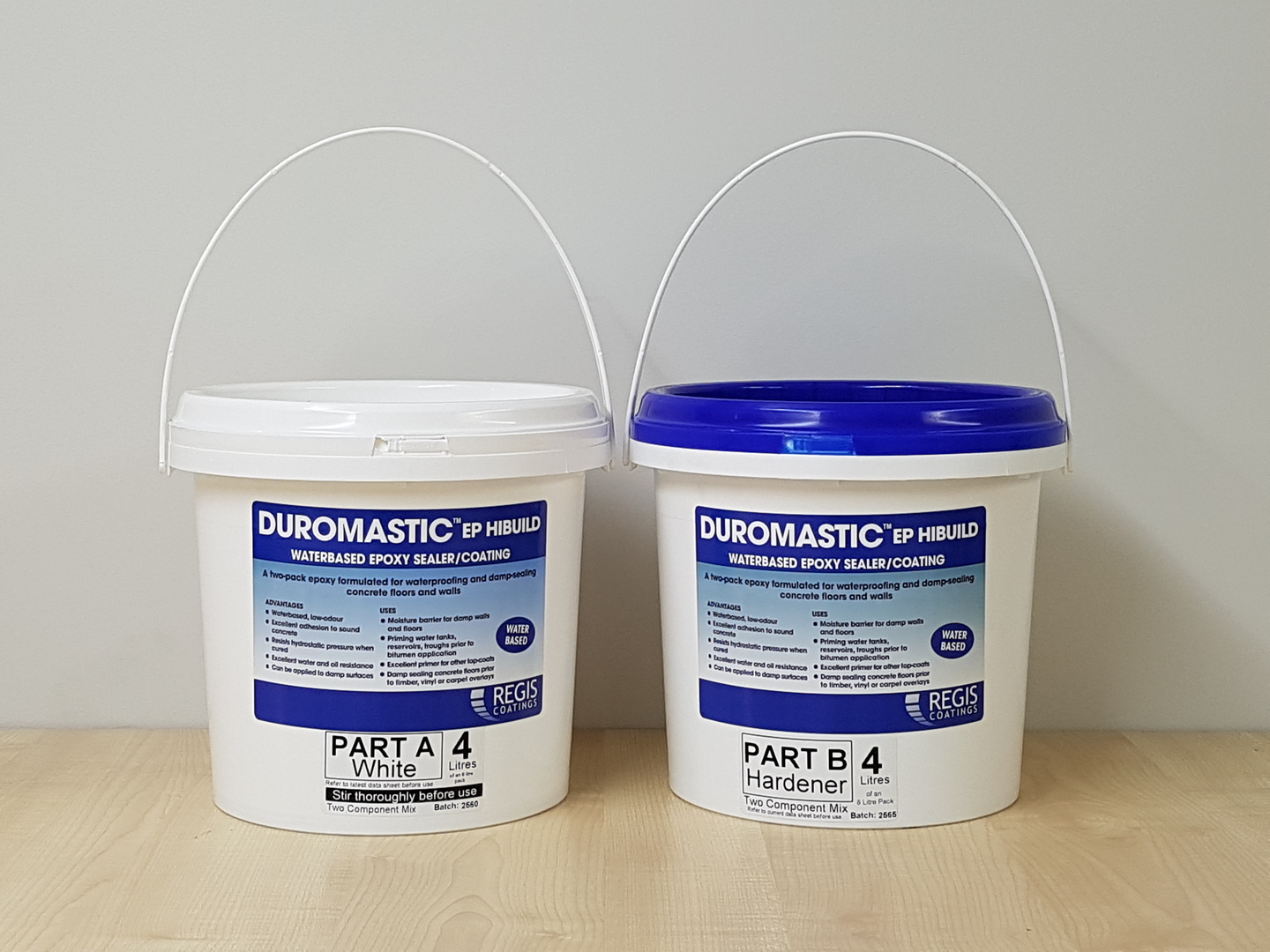

Water Based Epoxy Waterproof Coating White 4L

$155.25 Original price was: $155.25.$138.00Current price is: $138.00. incl. GST

Save: $15.00 (11.1%)

$120.00 excl GST

Shipping calculated at checkout.

- Nationwide Delivery

- Pick up from Trade Products Rosedale ( Call 09 320 4860 to confirm)

Two pack water based epoxy membrane/barrier coating designed for sealing damp interior concrete floors and walls. It will withstand very high levels of hydrostatic pressure.

Coverage: ranges between 4 – 10 sqm/litre.

- Waterbased non-toxic epoxy, easy to mix

- Moisture barrier on damp walls and floors

- Sealing damp floors prior to carpet or tile overlays

- Basements and Underground car parks

- Prevents rising damp and formation of efflorescence

- Can be applied to damp surfaces

- TDS

- MSDS

Water Based Epoxy Coating is ideal as a primer paint for butynol roofing. When used as a primer for butynol decks and balcony roofs, it should then be overcoated with a suitable acrylic roof paint. Also used to prime concrete and fibre cement sheet prior to applying Duromastic Bitumen and Acrylic paint systems.

Water Based Epoxy Coating may be applied to a damp concrete surface prior to laying carpet to protect the carpet from rising damp.

Products Features

- Two-pack non-toxic epoxy, easy to mix 1:1

- Withstands the forces of rising damp

- Thixotropic to ensure minimal sag while curing

- Can be applied in heavy coats on vertical surfaces

- May be applied to damp concrete

- Fast setting

HOW TO APPLY

Surface Preparation

Ensure the substrate is in clean and sound condition. The surface shall be free of dirt, oil, grease, moss and loose material and may be slightly damp. Pre-painted surfaces must be dry, any loose or bubbling paint must be removed.

Cracks should be gauged out using a diamond cutting blade on an angle grinder, then filled with an epoxy mortar. Any joints/cracks subject to movement should be filled with MS/PU flexible sealant.

Mixing Directions

Wear impervious gloves, such as latex or vinyl disposable gloves. Take an equal quantity of each Part A and Part B and mix thoroughly until a consistent mix is obtained. A spiral mixer on a low-speed drill is recommended. Scrape the edges of the mixing pail to ensure that no unmixed ingredient is on the sides or bottom of the pail.

Application

Once mixed the working time is approximately 1 hour. Apply the mixed coating to the prepared surface evenly by brush or roller. The choice of roller sleeve will depend on the substrate type, eg. for concrete block or rough surfaces, use a 20-30mm sleeve. For smooth concrete use a 10mm sleeve.

CLEANING OF TOOLS

Equipment and tools should be cleaned immediately after use with warm water and detergent, as cured material is hard to remove. A new roller sleeve is essential for each coat.

COVERAGE

The coverage rate of Duromastic EP Hibuild is typically about 5sqm / litre, per coat. But obviously this rate can vary in some situations. Very porous concrete such as concrete block walls will tend require a heavier rate of application than surfaces which are smooth.

Coverage rate of Duromastic EP Hibuild (per coat) ranges between 4 – 10 sqm/litre.

Apply by brush or roller. For concrete block walls, use a 20-30mm roller sleeve, designed for rough surfaces. For smooth surfaces, use a 12mm roller (semi-rough). Use a new roller sleeve each day.

*The information provided in this technical bulletin is as up-to-date and correct in detail as possible and is intended to give a fair description of the product and its capabilities. The user of these materials must satisfy themselves with the suitability for a particular application. If unsure about use with certain chemicals, please contact the manufacturer.

| Weight | 4 kg |

|---|---|

| Size | 4L, 8L, 20L |

| Colour | White, Light Grey |

Related Products

Related products

-

Sale

AQUEPOXY08DIY Kits

AQUEPOXY08DIY KitsAquepoxy DampStop Waterbased Epoxy Coating 8L

$316.25Original price was: $316.25.$292.10Current price is: $292.10. incl. GSTSave: $21.00 (7.6%)

Add to cart -

Sale

CRETEXAR4DIY Kits

CRETEXAR4DIY KitsDriveway and Masonry Sealer – Clear 4L

$155.25Original price was: $155.25.$138.00Current price is: $138.00. incl. GSTSave: $15.00 (11.1%)

Add to cart -

Sale

EPTSL250DIY Kits

EPTSL250DIY KitsWater Based Epoxy Floor Screed 10L

$291.95Original price was: $291.95.$240.35Current price is: $240.35. incl. GSTSave: $44.87 (17.7%)

Add to cart